Machining with a lathe has unique challenges.

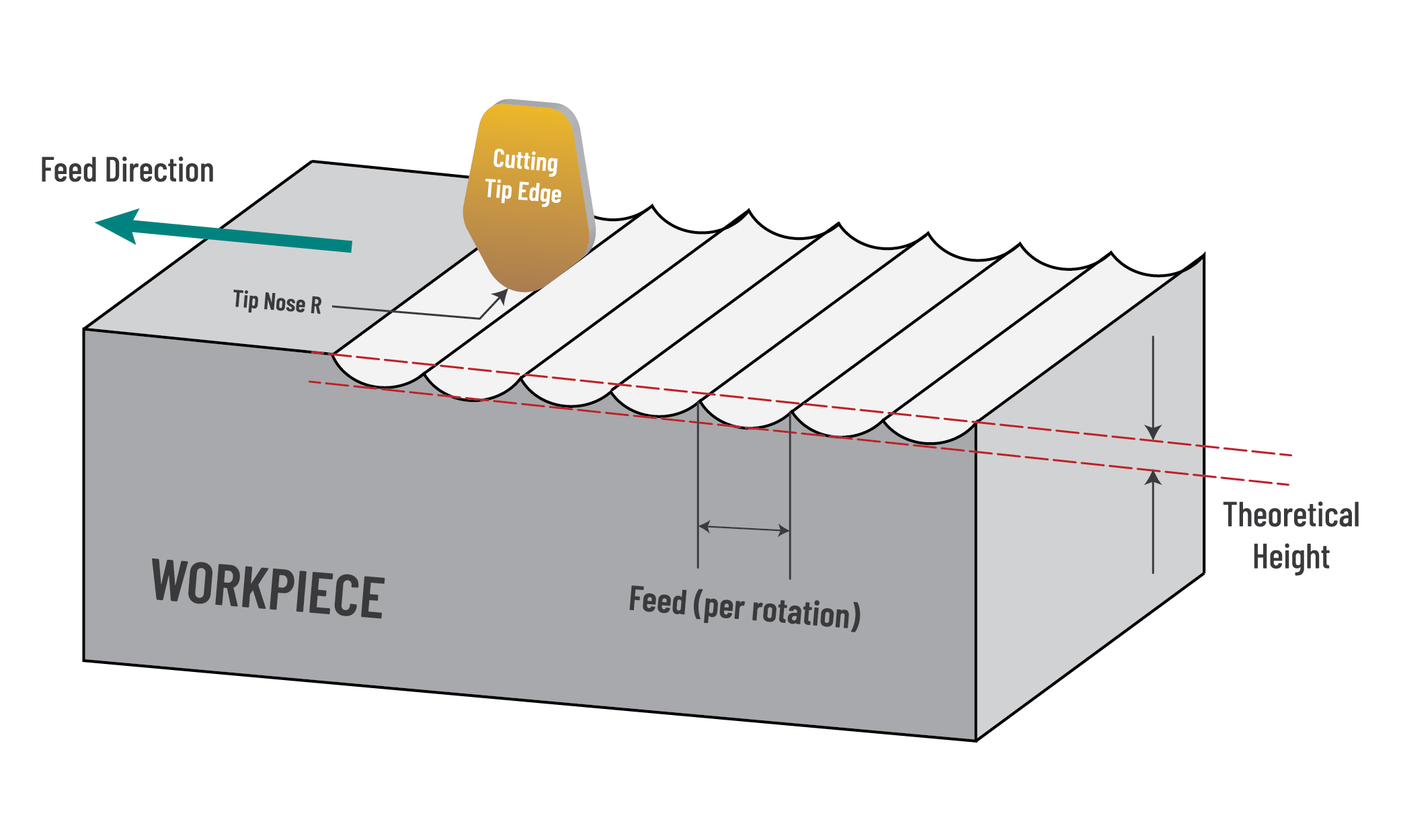

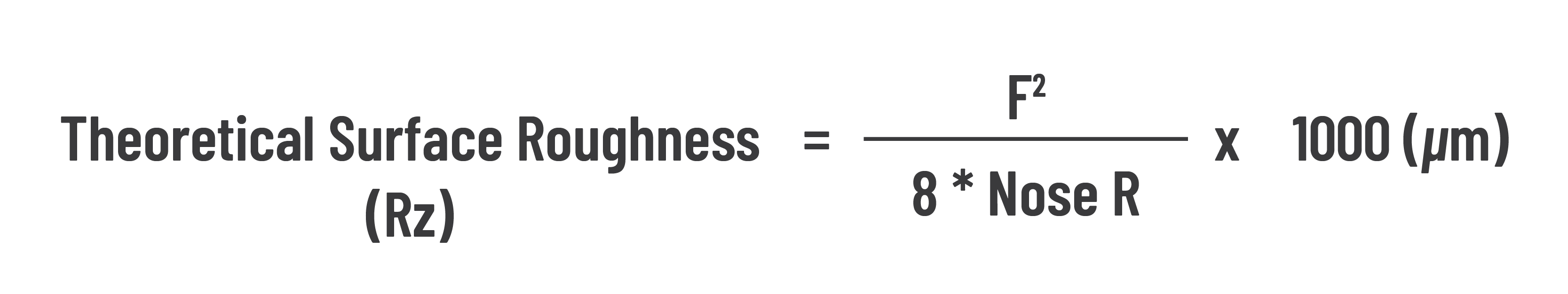

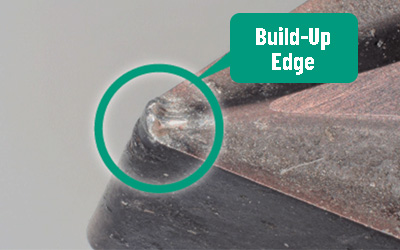

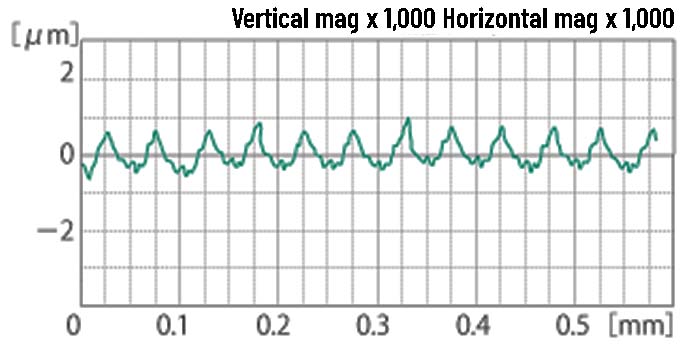

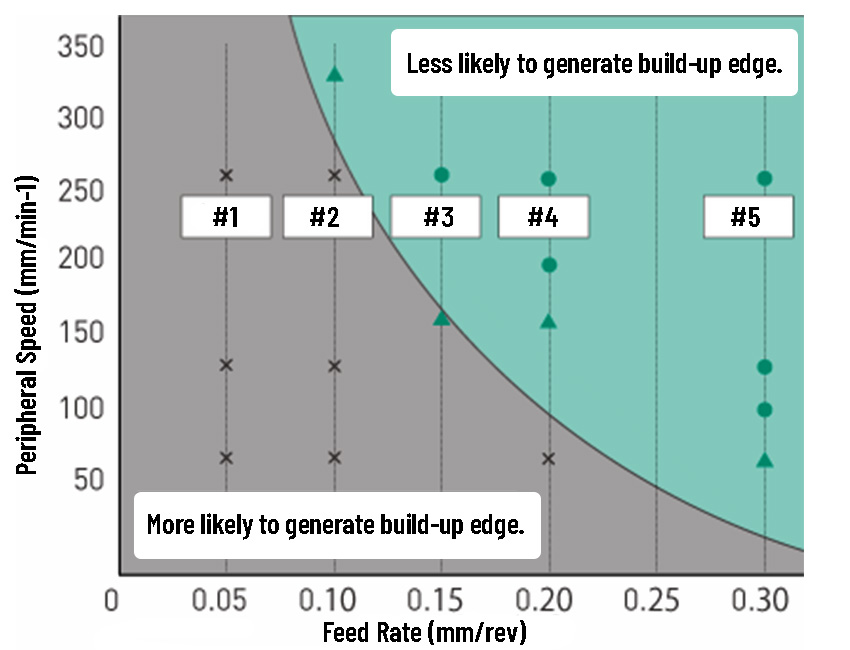

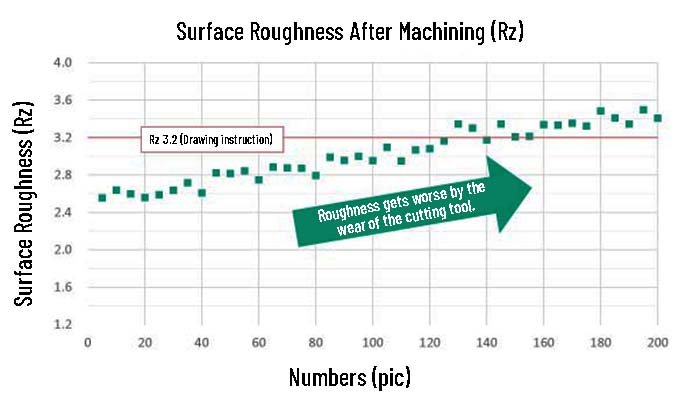

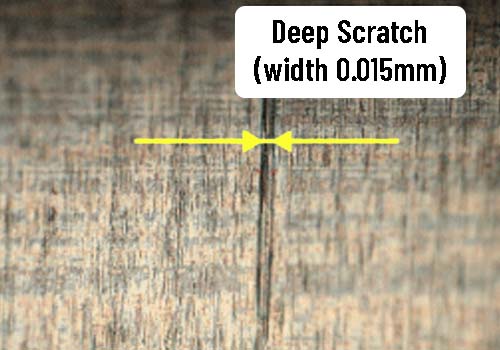

Inconsistencies in surface roughness

Shortened life for cutting tips

Adding a grinding process with another machine

Superoll™ is the answer.

ROLLER BURNISHING

What is Superoll?

Superoll is a full line of roller burnishing tools that create smoother finishes through compressing the surface - without removing material.LEARN MORE

Explore example case studies

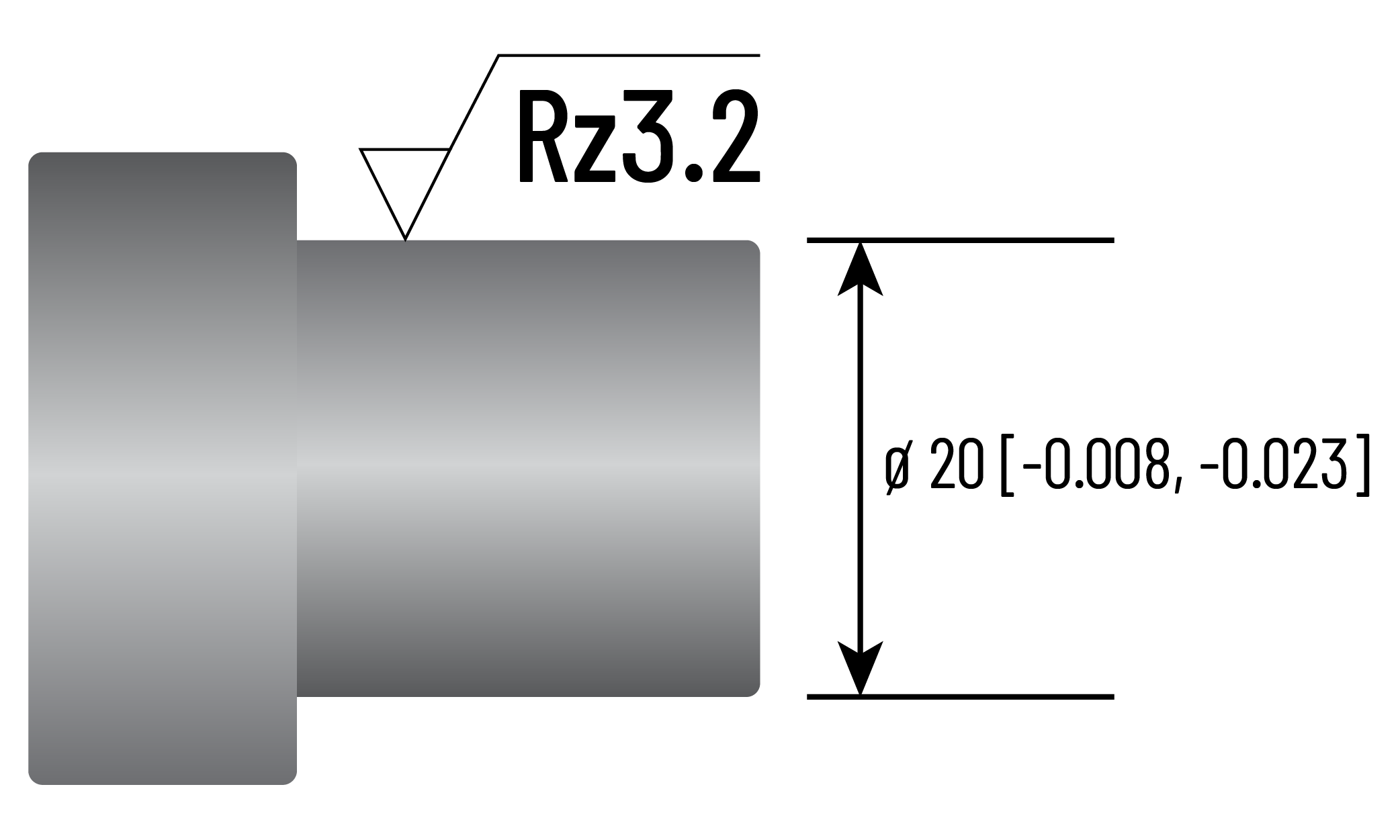

Quality and Precision

These hardened and highly polished tools integrate into machining centers to eliminate secondary processes such as grinding and honing, without removing any material.

A Mirror-Like Finish

Ideal for processing with shorter cycle times to improve productivity and reduce costs.Comparing Conventional Methods with Using Superoll in your Lathe

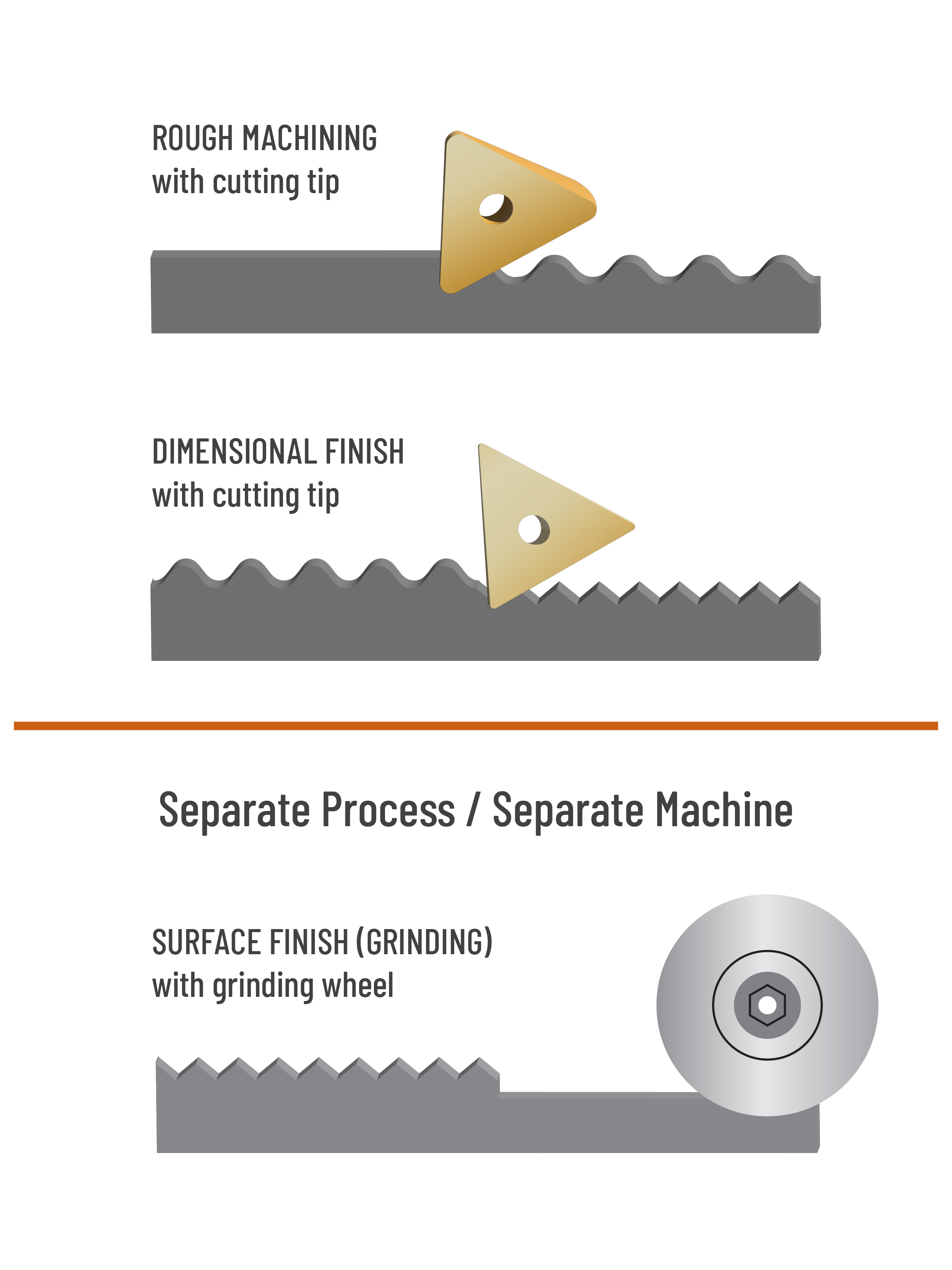

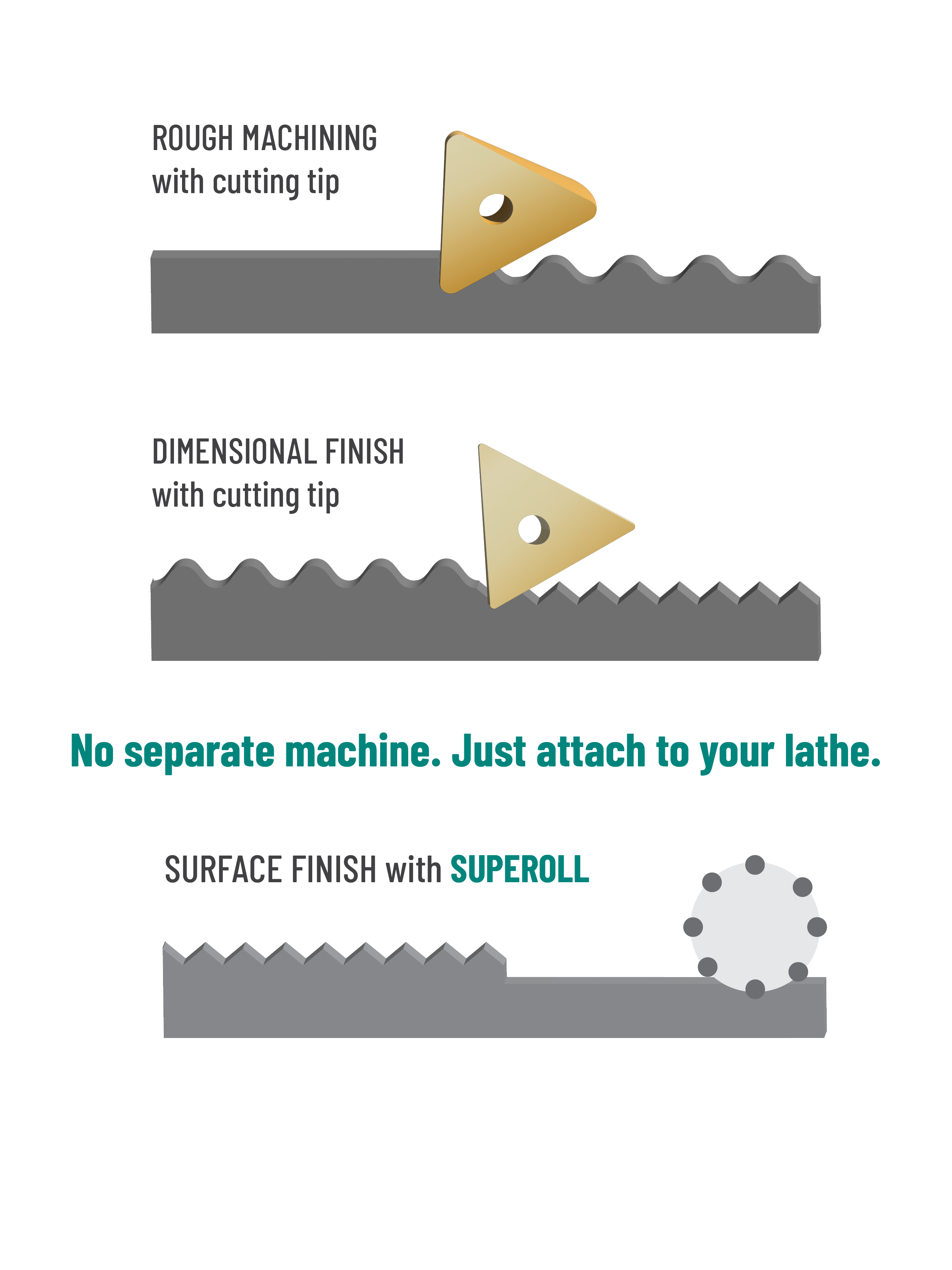

Rough Machining + Dimensional Finish + Surface Finish

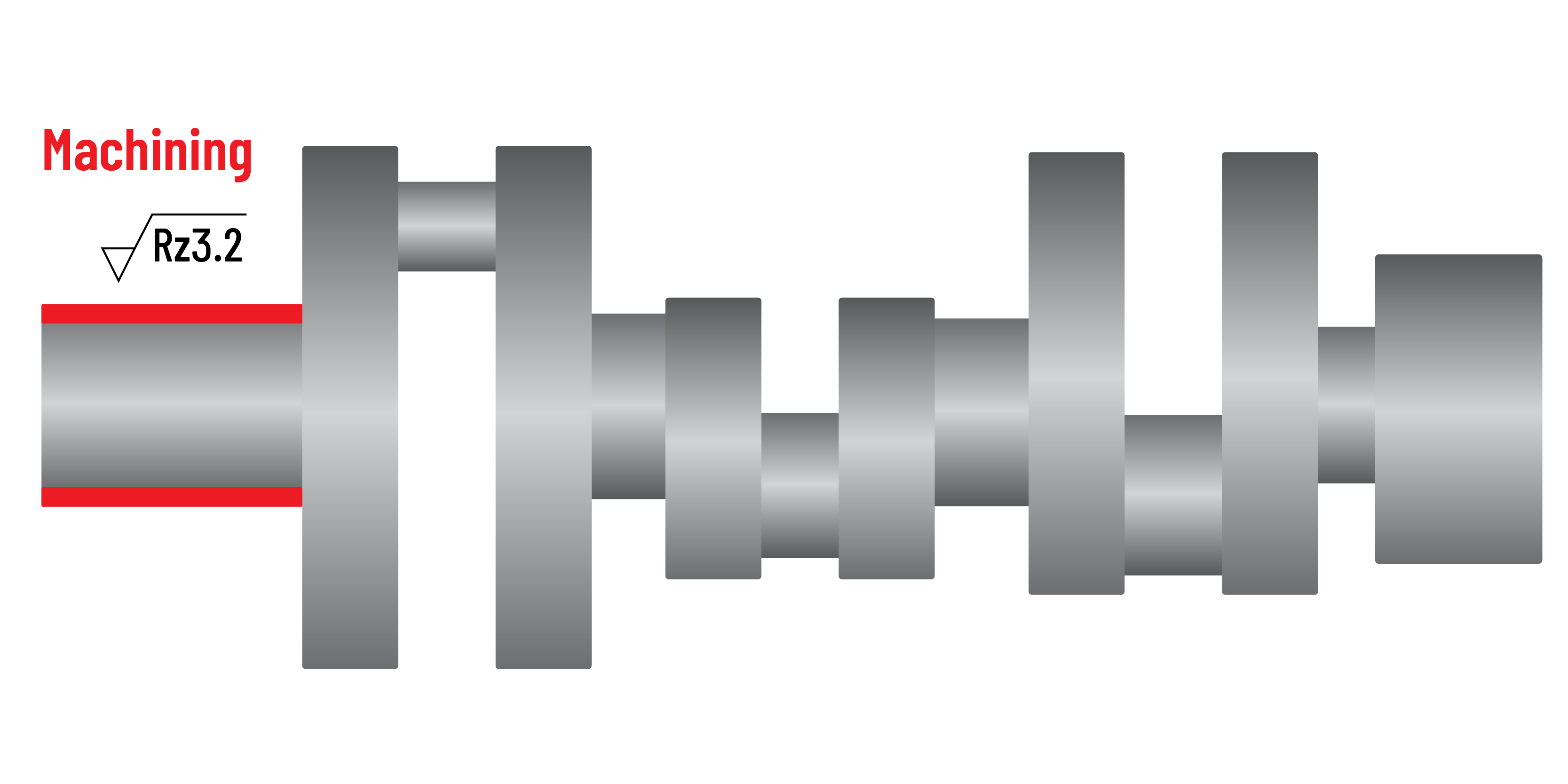

Lathe Machining the Conventional Way

The conventional way involves rough machining with a cutting tip first, then dimensional finish. From there, a separate process and machine is often needed to achievee the desired surface finish result.

Lathe Machining with Superoll

Using Superoll, you can achieve the precise dimensional accuracy and surface roughness at the same time - and you only need to attach it in your lathe. No separate process needed.

We're ready to help you find the right Superoll™ solution

Frequently

Asked

Questions

Single Roller Type - Product Lineup

SR5A

For shaft end surface

SR16M

For shaft end surface, taper, R surface

SR5C

For inner

SR16C

For inner

SR3Z

For outer groove side

SR3ZH

For inner groove side

SR24MW

For outer groove bottom

CEZF

For end groove surface

CEZH

For inner groove bottom

Materials

Acceptable Materials

Iron and non-ferrous material, including:

- Stainless

- SCM

- S45C

- FC

- ADC

- Copper

- Brass

Not For

- Titan

- Magnesium

- Wood

- Glass

- Ceramic

- Plastic